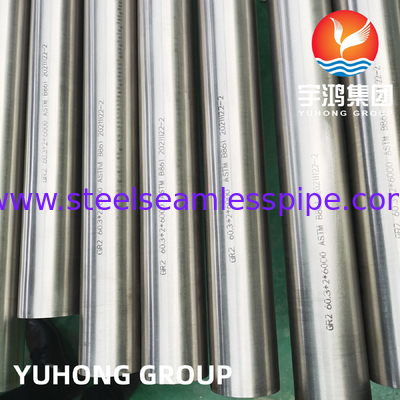

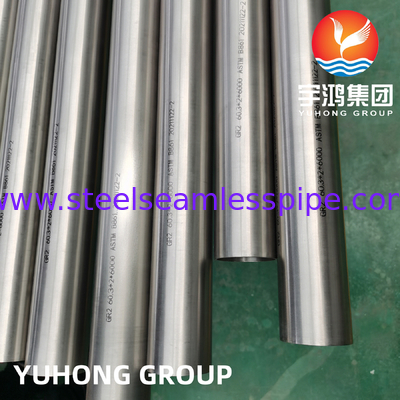

Tubo sem costura de liga de titânio ASTM B861 grau 2 UNS R50400

O tubo sem costura de liga de titânio ASTM B861 grau 2 é feito de titânio puro industrial, que combina excelente resistência à corrosão, resistência média e boa ductilidade.A sua estrutura perfeita é obtida por extrusão ou laminagem, sem o risco de defeitos de solda, e é adequado para ambientes de alta pressão e adversos.

Este material tem uma excelente resistência à água do mar, cloretos, vários ácidos e álcalis, e é de baixa densidade (alta relação resistência/peso), não magnético e biocompativel.

As aplicações típicas incluem oleodutos químicos, sistemas de plataformas offshore, equipamentos de dessalinização de água do mar e trocadores de calor.É o material preferido para condições corrosivas que exigem longa vida e alta confiabilidade, mas deve ser prestada atenção ao elevado custo e à protecção contra a corrosão galvânica quando ligada a outros metais.

Composição química dos tubos sem costura de titânio ASTM B861 grau 2

| Elementos |

Composição química % |

| Grau 1 |

Grau 2 |

Grau 3 |

Grau 5 |

Grau 7 |

Nível 9 |

Grau 11 |

Grau 12 |

Grau 23 |

| Nitrogénio, no máximo |

0.03 |

0.03 |

0.05 |

0.05 |

0.03 |

0.03 |

0.03 |

0.03 |

0.03 |

| Carbono, no máximo |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

| Hidrogénio, no máximo |

0.015 |

0.015 |

0.015 |

0.015 |

0.015 |

0.015 |

0.015 |

0.015 |

0.0125 |

| Ferro, máximo |

0.20 |

0.30 |

0.30 |

0.40 |

0.30 |

0.25 |

0.20 |

0.30 |

0.25 |

| Oxigénio, máximo |

0.18 |

0.25 |

0.35 |

0.20 |

0.25 |

0.15 |

0.18 |

0.25 |

0.13 |

| Alumínio |

- Não. |

- Não. |

- Não. |

5.5-6.75 |

- Não. |

2.5-3.5 |

- Não. |

- Não. |

5.5-6.5 |

| Vanádio |

- Não. |

- Não. |

- Não. |

3.5-4.5 |

- Não. |

2.0-3.0 |

- Não. |

- Não. |

3.5-4.5 |

| Cinza |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

| Ruthenium |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

| Palladio |

- Não. |

- Não. |

- Não. |

- Não. |

0.12-0.25 |

- Não. |

0.12-0.25 |

- Não. |

- Não. |

| Molibdênio |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

0.2-0.4 |

- Não. |

| Cloreto de sódio |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

| Níquel |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

0.6-0.9 |

- Não. |

| Nióbio |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

| Zicónio |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

| Silício |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

- Não. |

| Resíduos, no máximo, cada um |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

| Resíduos, total máximo |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

| Titânio |

balanço |

balanço |

balanço |

balanço |

balanço |

balanço |

balanço |

balanço |

balanço |

Resistência à tração dos tubos sem costura de titânio ASTM B861 grau 2

| Grau |

Resistência à tração, min |

Força do rendimento (0,2% de compensação) |

De largura igual ou superior a 50 mm |

| |

Min |

Max. |

| Ksi |

(Mpa) |

Ksi |

(Mpa) |

Ksi |

(Mpa) |

comprimento de medição min % |

|

| Grau 1 |

35 |

(240) |

25 |

(170) |

45 |

(310) |

24 |

| Grau 2 |

50 |

(A) |

40 |

(275) |

65 |

(450) |

20 |

| Grau 3 |

65 |

(450) |

55 |

(380) |

80 |

(550) |

18 |

| Grau 5 |

130 |

(895) |

120 |

(828) |

- Não. |

- Não. |

10 |

| Grau 7 |

50 |

(A) |

40 |

(275) |

65 |

(450) |

20 |

| Nível 9 |

90 |

(620) |

70 |

(483) |

45 |

- Não. |

15 |

| Grau 11 |

35 |

(240) |

25 |

(170) |

- Não. |

(310) |

24 |

| Grau 12 |

70 |

(483) |

50 |

(A) |

- Não. |

- Não. |

18 |

| Grau 23 |

120 |

(828) |

110 |

(759) |

- Não. |

- Não. |

10 |

Aplicação

Química e petroquímica

Tubulações de processo, reatores e tubulações de trocadores de calor para transporte de meios altamente corrosivos (como íons cloreto, soluções ácidas e ácidos orgânicos).

Substituir o aço inoxidável em ambientes de alta temperatura e de alto teor de cloro, onde é suscetível a ocorrência de corrosão por fenda ou tensão, prolongando significativamente a vida útil do equipamento.

Engenharia marítima e navios

Sistemas de refrigeração de água do mar, oleodutos e gasodutos submarinos e colectores de alta pressão da plataforma de perfuração.

Resistem à corrosão da água do mar e à fixação biológica, reduzem os custos de manutenção e são adequados para ocasiões com longos ciclos de serviço.

Energia e protecção do ambiente

Tubos de evaporação e tubos de aquecimento de salmoura em dispositivos de dessalinização de água do mar

Tubos de pulverização do sistema de dessulfuração de gases de combustão (FGD), revestimentos de chaminés

Sistemas industriais de ponta

Tubulações hidráulicas de aviação, tubulações de combustível aeroespacial

Tubulações limpas de bioengenharia e farmacêutica

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!