Tubo com aleta HFW U Bend de aço carbono ASTM A106 Gr.B para economizadores de exaustão de motores diesel

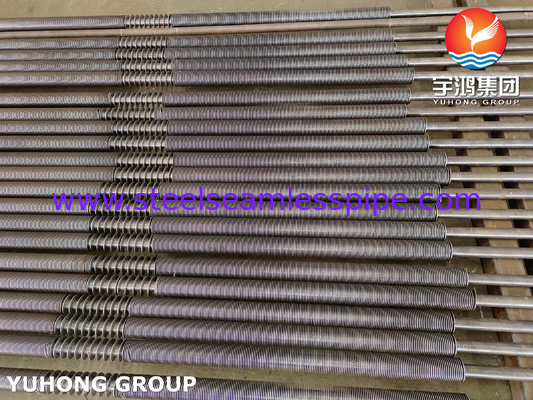

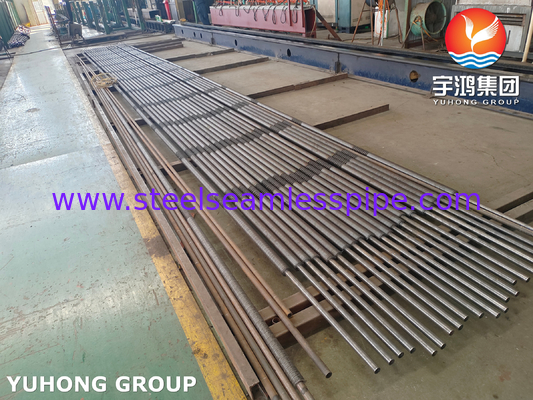

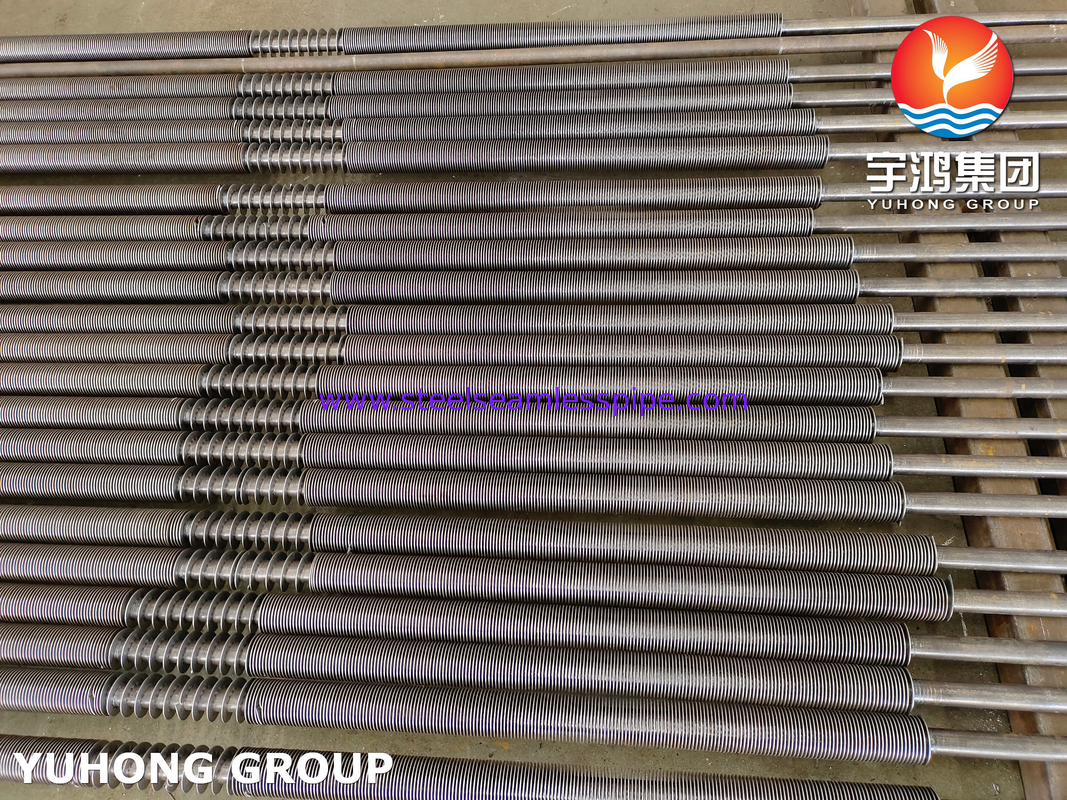

Os tubos aletados em U de aço carbono A106 Gr.B são elementos de transferência de calor altamente eficientes. O tubo base é feito de aço carbono ASTM A106 Grau B. As aletas externas são fixadas helicoidalmente ao tubo base para aumentar significativamente sua área de superfície externa. A corrente de alta frequência gera efeitos de pele e proximidade, gerando instantaneamente calor elevado nos pontos de contato entre o tubo base e o material da aleta, fazendo com que derretam e se fundam sob pressão.

Os tubos aletados são dobrados em forma de "U" fechado.

Composição Química de Tubos e Tubos Sem Costura de Aço Carbono ASME SA / ASTM A106 GR.B:

| Composição Química (%) |

| Grau |

C(Máx) |

Mn |

Si(Mín) |

Cu(Máx) |

Ni(Máx) |

Cr(Máx) |

Mo(Máx) |

V(Máx) |

P(Máx) |

S(Máx) |

| B |

0,3 |

0,29~1,06 |

0,1 |

0,4 |

0,4 |

0,4 |

0,15 |

0,08 |

0,035 |

0,035 |

Propriedades mecânicas de tubos e tubos SMLS de Grau B A 106:

| Propriedades Mecânicas: |

| Grau |

Resistência à tração (Mpa), Mín. |

Resistência ao escoamento (Mpa), Mín. |

| B |

415 |

240 |

Sólido

Processo: A fita de aço é alimentada na máquina de soldagem de alta frequência em estado liso. Sob corrente e pressão de alta frequência, a raiz lisa da fita derrete e solda-se à superfície do tubo base instantaneamente.

Vantagens:

O processo é maduro, eficiente e o principal no mercado.

A condutividade térmica ideal é alcançada porque a zona de solda é contínua e completa.

Adequado para tubos base de várias especificações, incluindo tubos de paredes finas.

Denteado

Punção: Serrilhas uniformes são perfuradas na raiz da fita da aleta.

Ranhura: Ranhuras espirais rasas são pré-laminadas na superfície do tubo base.

Inserção e soldagem: A fita da aleta dentada é enrolada e pressionada nas ranhuras, fazendo com que os dentes se deformem plasticamente e se encaixem no tubo base. A soldagem de alta frequência é então realizada. A soldagem ocorre não apenas na raiz da aleta, mas também nas lacunas entre os dentes e o tubo base.

Vantagens:

Mesmo que haja áreas minúsculas de soldas incompletas, os dentes mecanicamente interligados fornecem forte resistência à extração, reduzindo significativamente o risco de falha geral.

Excelente resistência à fadiga: A estrutura mecanicamente interligada resiste efetivamente às tensões térmicas alternadas causadas por partidas e paradas frequentes e flutuações repentinas de temperatura, evitando rachaduras induzidas por fadiga nas raízes das aletas.

Aplicação

Geradores de vapor de recuperação de calor (HRSGs): Usados em economizadores ou seções de evaporadores para recuperar calor do escapamento da turbina a gás.

Pré-aquecedores de ar: Usam gases de combustão quentes para aquecer o ar de combustão da caldeira.

Caldeiras de tubos aletados: Usadas para gerar os tubos dentro da caldeira.

Aquecedores/resfriadores de gás de processo: Usados nas indústrias petroquímica e de refino.

Aquecedores de óleo térmico: Usam óleo térmico como fluido do lado do tubo para aquecer ar ou outros gases.

Economizadores de exaustão de motores diesel.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!