- Os produtos da marca YUHONG já foram exportados para mais de 85 países. Com mais de 35 anos de experiência, devido à rigorosa política de controle de qualidade, excelente serviço de vendas e entrega no prazo, a YUHONG conquistou cada vez mais novos clientes e obteve mais e mais pedidos repetidos de clientes antigos. Na mente do povo YUHONG: Qualidade é o Primeiro Importante!

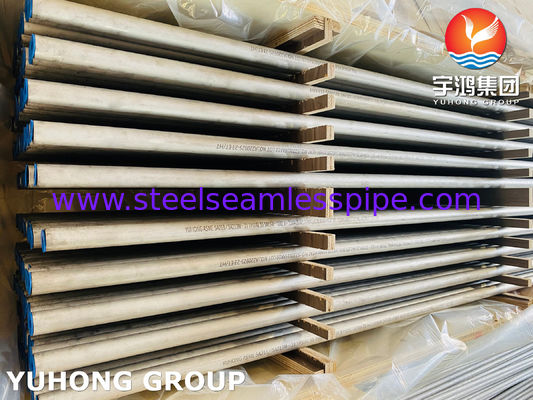

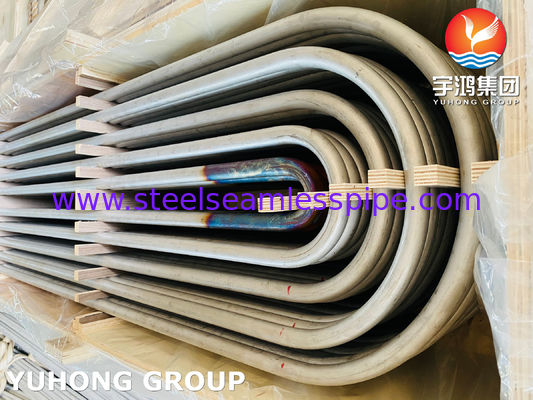

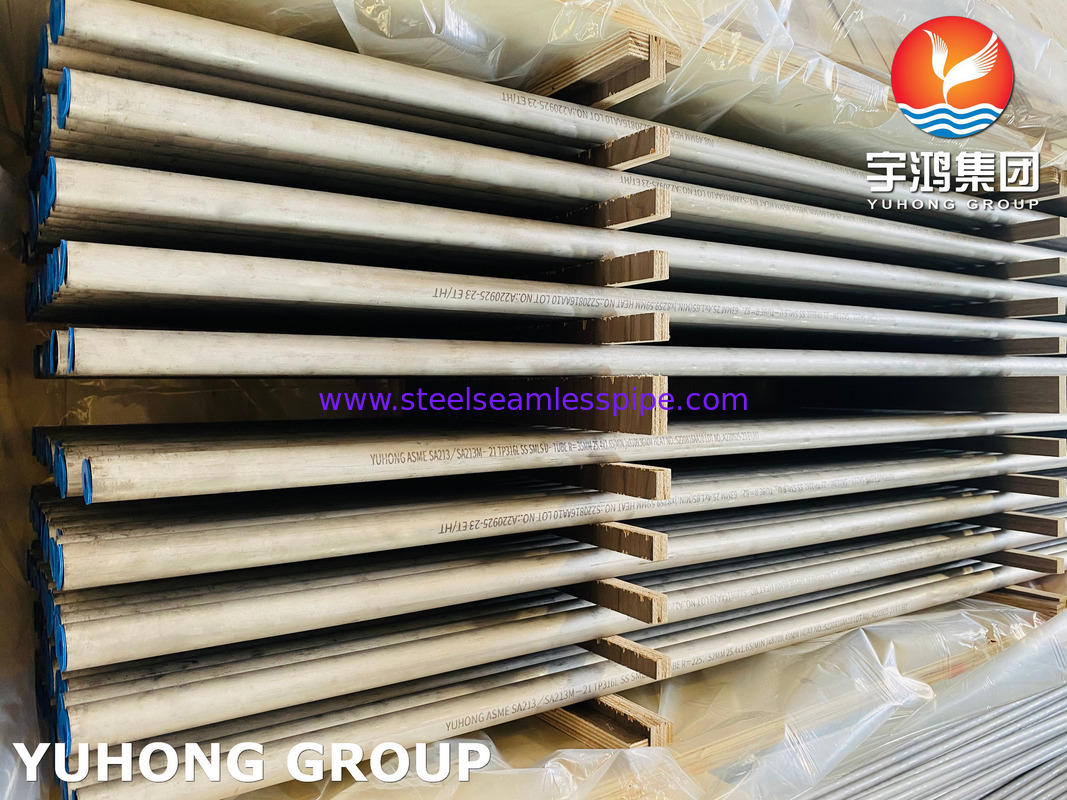

Tubo em U de Aço Inoxidável ASTM A213 TP316L para Caldeira e Trocador de Calor

Este produto é um tubo em U de alto desempenho projetado especificamente para caldeiras, superaquecedores, trocadores de calor e condensadores que operam em ambientes de alta pressão, alta temperatura e corrosivos. Fabricado em ASTM A213 TP316L, um aço inoxidável austenítico de baixo carbono, oferece resistência superior à corrosão, alta resistência à temperatura e excelente conformabilidade e soldabilidade, tornando-o um componente crítico para a eficiência térmica e a confiabilidade a longo prazo do equipamento.

1. Propriedades Químicas e Mecânicas

Composição Química (%) ASTM A213 TP316L

|

| C |

Mn |

P |

S |

Si |

Cr

|

Ni

|

Mo

|

|

≤ 0,35%

|

≤ 2,00%

|

≤ 0,045% |

≤ 0,03% |

≤ 1,00% |

16%-18% |

10,00%-14,00% |

2,00%-3,00% |

Propriedades Mecânicas

| Resistência à Tração |

Resistência ao Escoamento |

Alongamento (em 50mm) |

Dureza |

| ≥485 MPa |

≥170 MPa |

≥35% |

≤217 HB (Brinell) |

Faixa de Tamanho Disponível

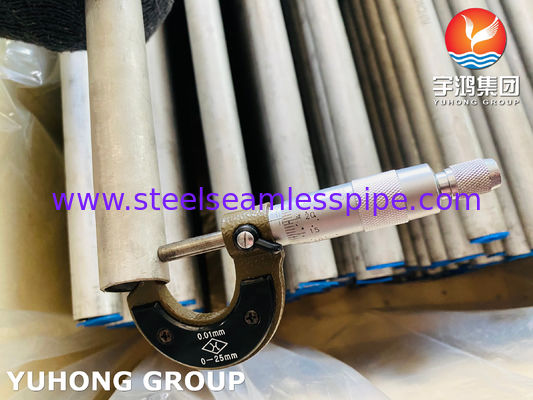

Diâmetro Externo (DE): Faixa comum de 9,53 mm (3/8") a 25,4 mm (1"), outros tamanhos disponíveis sob consulta.

Espessura da Parede (EP): Faixa comum de 0,8 mm a 2,5 mm (correspondente a diferentes DEs).

Raio da Curva em U (R): Personalizado de acordo com o projeto do cliente e o layout do feixe de tubos.

Comprimento da Perna Reta: Cortado com precisão de acordo com os desenhos do cliente.

2. Principais Vantagens

- Resistência Superior à Corrosão

A adição de Molibdênio (Mo) em TP316L oferece resistência aprimorada à corrosão por pites e fendas em comparação com a série 304, tornando-o ideal para ambientes contendo cloreto.

- Teor de Carbono Ultrabaixo

A classe "L" denota um teor máximo de carbono de 0,030%, o que minimiza o risco de precipitação de carbonetos durante a soldagem e a exposição à faixa de temperatura de sensibilização (425-860°C), evitando assim a corrosão intergranular.

- Excelentes Propriedades em Alta Temperatura

Mantém boa resistência mecânica e resistência à fluência em temperaturas elevadas, garantindo a integridade estrutural durante o serviço prolongado.

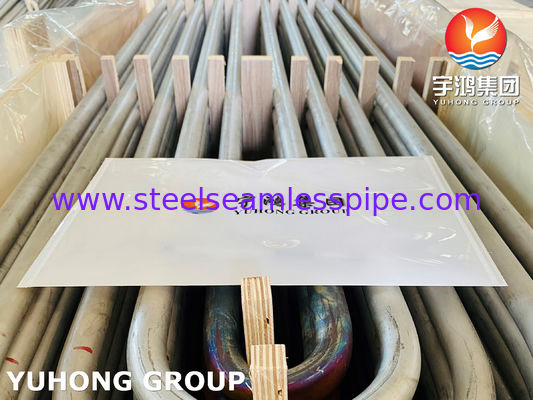

- Processo de Curvatura em U de Precisão

Técnicas avançadas de curvatura garantem espessura de parede uniforme, sem enrugamento ou afinamento excessivo na curva em U. A superfície interna lisa minimiza a queda de pressão e mantém a eficiência consistente de transferência de calor.

3. Principais Aplicações

Trocador de Calor (lado da carcaça menos corrosivo) —— Para lidar com a expansão térmica

Condensador / Resfriador de Água do Mar —— Resistir à corrosão por íons cloreto

Caldeira / Superaquecedor —— Resistência a altas temperaturas e resistência à oxidação

Processamento Petroquímico e Químico —— Resistir à corrosão intergranular após a soldagem

----------------------------------------------------------------------------------------------------------------------------------------------------------------

Por que escolher nossos Tubos em U 316L?

- Rastreabilidade Completa: Cada lote de materiais possui um certificado de material completo para garantir a conformidade com os padrões e especificações.

-

Acabamento Superior: A tecnologia profissional de curvatura de tubos garante curvas em U sem defeitos, prolongando a vida útil do equipamento.

-

Soluções Personalizadas: Podemos fornecer produção personalizada precisa com base em seus desenhos e requisitos técnicos específicos.

-

Certificações Globais: Nossos produtos estão em conformidade com os padrões internacionais, como ASTM, ASME e EN, e atendem clientes em todo o mundo.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!