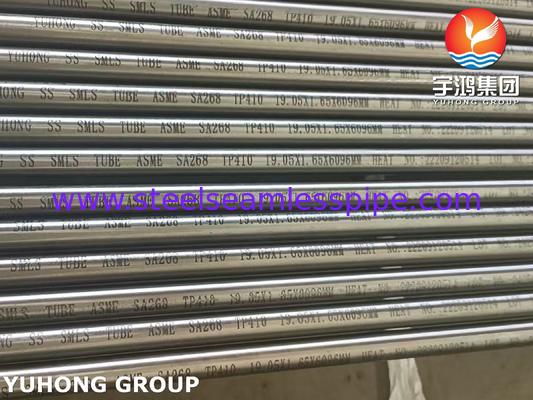

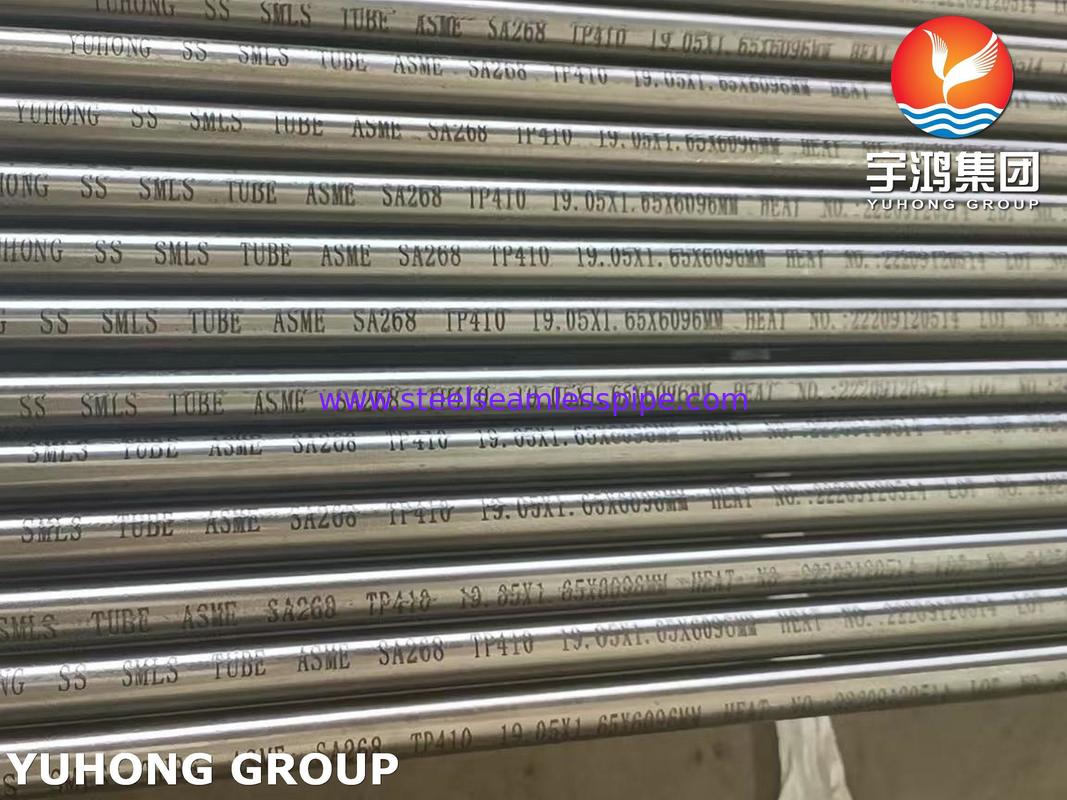

ASME SA268 TP410 Tubos de aço inoxidável sem costura

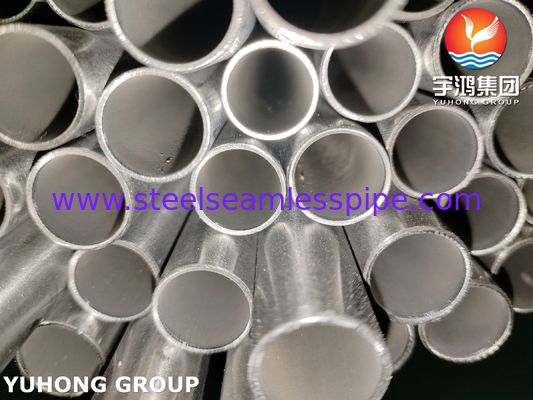

O tubo de aço inoxidável sem costura ASME SA268 TP410 é um tipo de martensítico amplamente utilizado conhecido por sua resistência moderada à corrosão, alta resistência e dureza.garante a integridade estrutural para aplicações sob pressãoEsta qualidade é normalmente fornecida em condições de tratamento térmico, tais como recozimento ou amortecimento e temperação, para atingir as propriedades mecânicas desejadas.que o tornam adequado para uma série de utilizações industriais, incluindo sistemas de vapor, tubos de poços de petróleo, trocadores de calor e componentes mecânicos.

O TP410 é um aço inoxidável de cromo martensítico básico contendo aproximadamente 11,5% de cromo, que fornece resistência à corrosão em ambientes moderados.é magnético e pode ser reforçado através de tratamento térmicoAs suas propriedades finais são em grande parte determinadas pela sua condição de tratamento térmico.

Composição química (%)

| Elementos |

C |

- Não |

Sim |

P |

S |

Cr |

Ni (facultativo) |

| Distância |

≤ 015 |

≤ 100 |

≤ 100 |

≤ 0040 |

≤ 0030 |

11.5-13.5 |

≤ 060 |

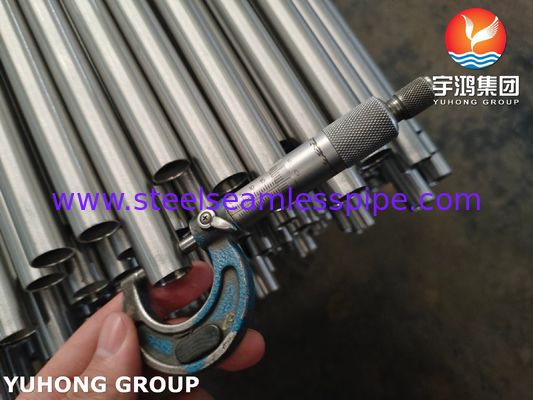

Propriedades mecânicas

| Resistência à tração |

Força do rendimento (0,2% de compensação) |

Prolongamento (% em 2 polegadas) |

Dureza (Brinell) |

| ≥ 415 MPa |

≥ 205 MPa |

≥ 25% |

≤ 217 HB |

Nota: O TP410 apagado e temperado pode atingir valores de resistência e dureza significativamente mais elevados.

Materiais equivalentes com referências comuns

| ASTM/ASME |

S.U.N. |

O que fazer? |

EN (Designação) |

JIS |

DIN |

| TP410 |

S41000 |

1.4006 |

X12Cr13 |

SUS 410 |

X10Cr13 |

Comparação: TP304 VS. TP410 VS. TP316

| Grau |

Características essenciais |

Guia de aplicação primária |

| TP304 |

Excelente formabilidade, boa resistência geral à corrosão. |

A escolha mais comum para serviços corrosivos gerais (por exemplo, alimentos, bebidas, produtos químicos). |

| TP410 |

Alta resistência e dureza; magnetismo; resistência moderada à corrosão. |

Selecionados pelas propriedades mecânicas (desgaste, resistência) em ambientes moderados (por exemplo, vapor, válvulas, talheres). |

| TP316 |

Superior resistência à corrosão, especialmente a cloretos e ácidos. |

A melhor escolha para ambientes agressivos (por exemplo, água do mar, processamento químico, celulose e papel). |

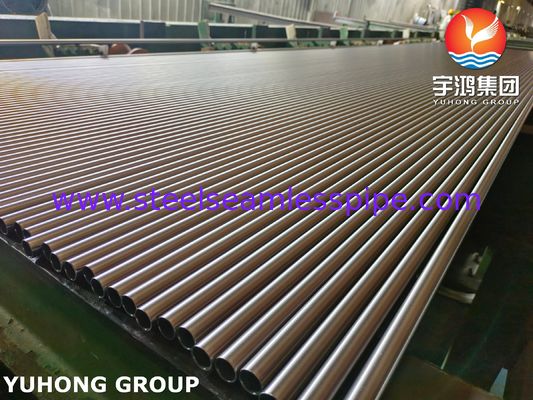

Aplicação do tubo de aço inoxidável sem costura ASME SA268 TP410

1Geração de energia:Tubos de vapor de baixa pressão, aquecedores de água de alimentação e condensados de vapor em condições de serviço moderadas.

2- Petróleo e Gás:Tubos de poço e linhas de fluxo para ambientes de produção doces (não ácidos).

3. Intercambiadores de calor:Intercambiadores de calor para meios como água doce, óleos e produtos químicos orgânicos.

4. Componentes mecânicos:Tubos hidráulicos de cilindros, mangas de rolamentos, buchas e mandrels que requerem resistência ao desgaste.

5Automóvel:Linhas de injecção de combustível e componentes específicos do sistema de escape.

6Engenharia Geral: Tubos de processo de alta pressão e partes estruturais de máquinas.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!